|

A Guide to Implementing the Theory of

Constraints (TOC) |

|||||

|

Replenishment – Adding Value Through The

Supply Chain Replenishment is the method by which we add

substantial value to the supply chain.

We achieve this by increasing the throughput generated from the final customer

– our constraint. In fact we must

subordinate our whole supply chain to the constraint. That is we make sure that we have exactly

the right stock, in the right place, whenever someone wants to buy it. Sound difficult? It’s not really. Not, if we think about what we are setting

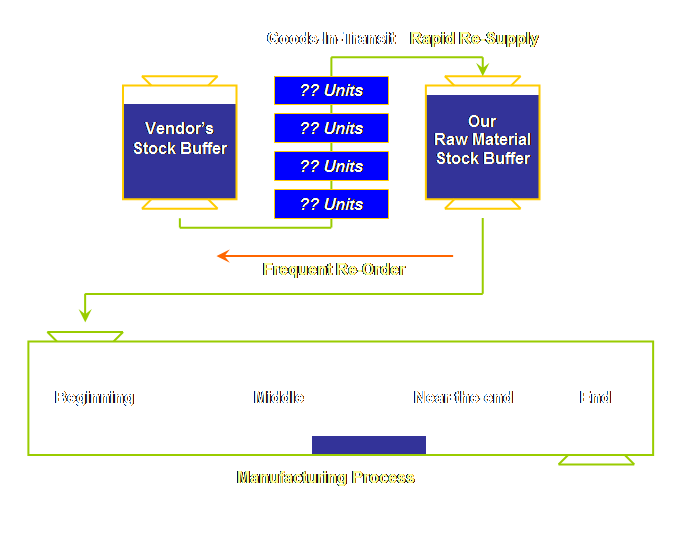

out to achieve. Let’s step back for a moment to the manufacturing

cases that we have examined and the step forward into supply chain. Previously, in section on production, we

discussed increasing the throughput in make-to-order environments, an

environment where timeliness is an explicit concern. We then examined make-to-stock and

make-to-replenish environments, places where timeliness is less obvious but

still a critical element. We

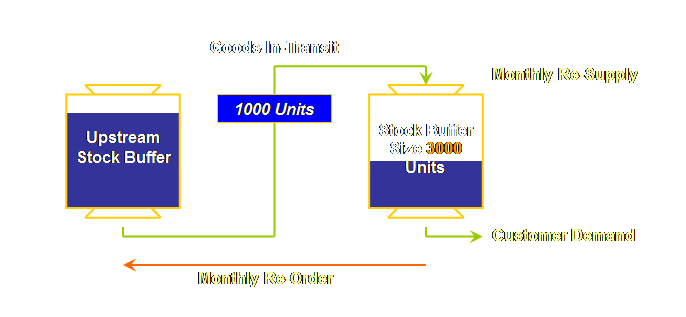

represented our make-to-stock environment something like this;

Of course not all businesses contain a production or

manufacturing process, that is, there may not be any transformation of goods

carried out in the process. Instead,

value is added by moving goods through both space (transportation) and time

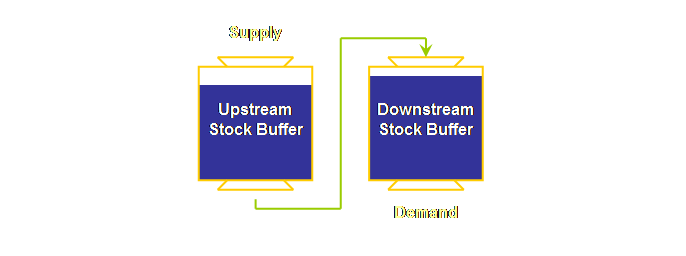

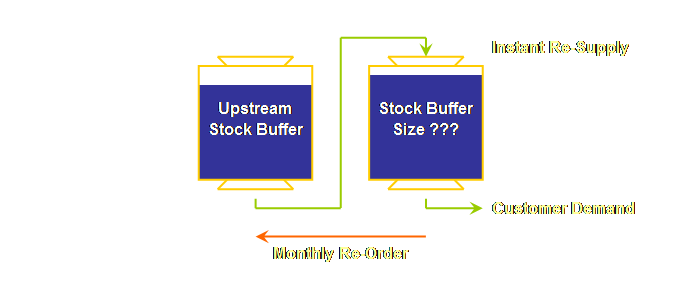

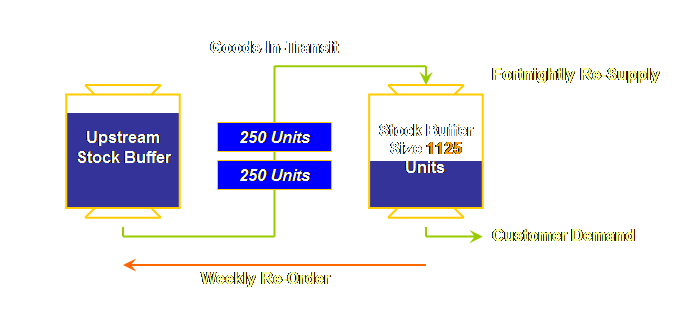

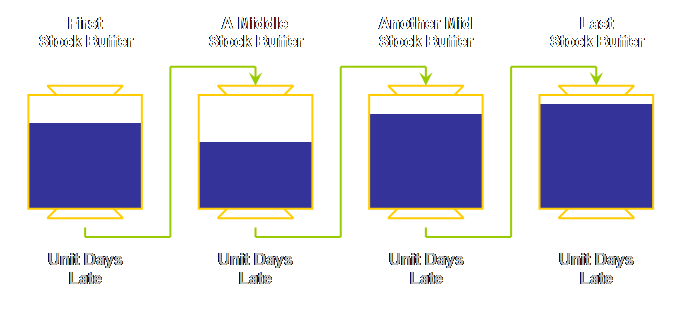

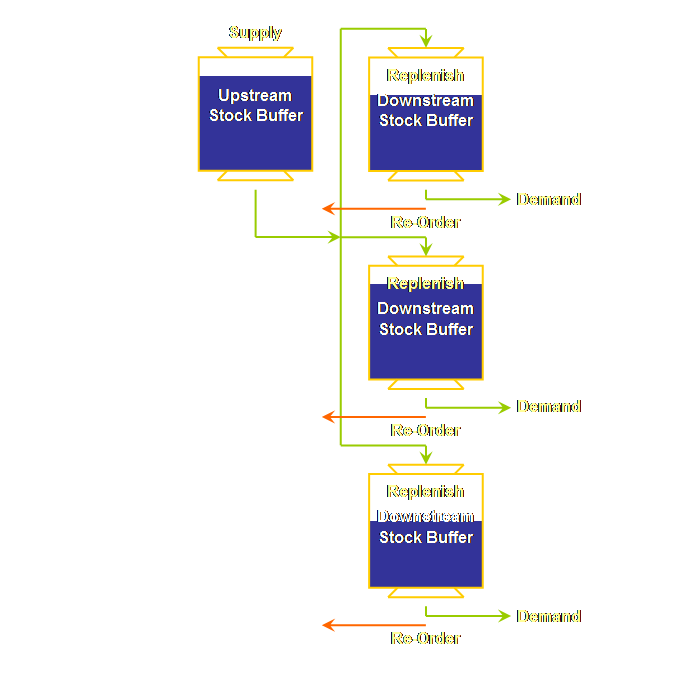

(storage) from a source of supply to the location of a demand. Rather than a flow from a process to a

stock buffer as in manufacturing, we now have a flow from stock buffer to

stock buffer. Let’s draw this.

Each node could represent the quantity of a single

type of stock unit in the chain as it passes from distributor to wholesaler

to retailer for instance. Equally we

could consider it to be the whole sum of all the different types of stock

units at each of these stages. The

diagram is generic; we can decide as the situation demands. Clearly we could also have hybrid systems with both

manufacturing and supply chain components, and the supply chain component

might not be linear; but let’s leave these interesting facets until the

distribution and marshalling pages. Replenishment is the motor for supply chain, it is the

mechanism that ensures that we never miss a sale by not having the right

material in the right place at the right time for the customer. Let’s have a closer look at the drivers of

replenishment, but first, if you have a manufacturing background you might

consider a small diversion. Replenishment can be broadly described, or defined, as

the frequent and rapid replacement of recent actual demand. The key is that there is no forecasting

into the future, only the rapid response to the very recent past. We address timeliness in supply chain by

the replenishment characteristics of our stock buffers. Through replenishment we can supply more

goods in total, to the right place, at the right time, and most often with

considerably less total stock in the system.

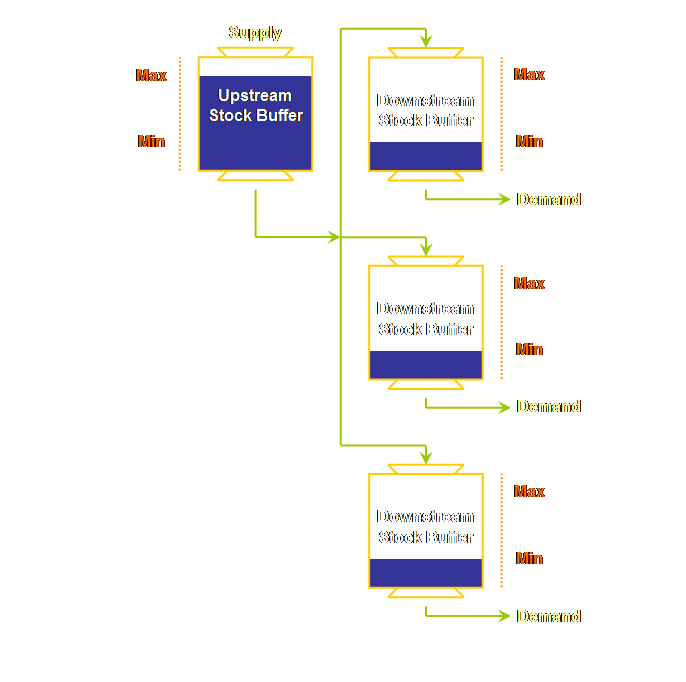

The objective of course is to increase Throughput. Each and every stock type at each and every node

becomes its own replenishment buffer.

The size and serviceability

of the stock buffers is driven by how frequently and how rapidly we

choose to replenish consumed stock and

this is how we configure the solution.

The configuration will depend upon the assumptions that we are willing

to challenge about batching; both batching in time and batching of quantity. Let’s draw this as a simple model.

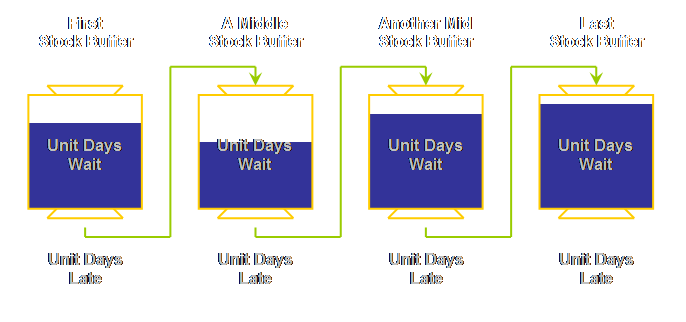

Locally, the buffers, once in operation, signal

replenishment quantities – our local prioritization system – they also absorb

many small variations as well as providing day-to-day exception reporting indicating

that there may be a potential stock supply violation – our local control. Let’s add these local features to our model.

Let’s now examine a little more about what we mean

by replenishment. Replenishment is one of those words, like for instance;

quality or strategy, which means different things to different people

depending upon their work environment and their experience. This is sufficient to cause quite a bit of

confusion. In fact, it is probably

fair to say that manufacturers have one view of replenishment and that supply

chains have another view. In general it seems that replenishment

of a stock buffer is composed of two critical components; Re-Ordering and Re-Supply However, I will argue that there are at least 4

components and that the two additional ones should be insignificant, or at

least rendered so. Nevertheless we

should recognize their existence; Re-Checking, Re-Ordering, Re-Supply, and

Re-Stocking Clearly, then, re-ordering and re-supply are the two

aspects that may require the longest durations and hence impinge most upon

our timeliness and the determination of the size of our buffers. We need to examine re-ordering and re-supply

separately before combining them together once again. In order to do this let’s exclude re-supply

for the moment by something similar to that which applied mathematician do;

“let us assume” re-supply is near instantaneous! If we do this then we can isolate some of

the assumptions about re-ordering. Let’s consider 2 re-ordering environments. 1. Fixed re-order quantity variable

re-order frequency – batch lot manufacturing 2. Variable re-order quantity fixed re-order frequency – shipment lot supply chain In fact there is a 3rd which we touched upon in

manufacturing make-to-stock on the drum-buffer-rope page and which we will

mention once again after considering the mechanism for determining buffer

status. However, of the two above, the

first, fixed-quantity, is very common in manufacturing, the world of batch

lots. The second is fixed-frequency

and is very common in supply chain, the world of shipment lots – and the

subject of this page. Clearly there is tremendous potential for people to

say “I understand what you mean by replenishment,” when indeed the

understanding is locked into the first case.

I know, “I’ve been there, done that.” So let’s work through both of these cases under the

assumption of near-instant re-supply.

Then we will have a look at the effect of non-instant re-supply, and

how to accommodate this as part of replenishment. If we think about it, all make-to-stock is

replenishment of sorts. If we make

4000 new things that are standard items, and they don’t age, then it really

doesn’t matter if we make a year’s supply and put them in the warehouse –

although it would be better to be privately owned to embark on such a mission

these days. Our only risk is that the

demand might be for more than this plus our safety stock before we get around

to producing these things again; therefore we might miss sales. If we sell less than 4000 in a year, then

we just won’t make the remainder next year and bring our stock back up –

right? So in effect we did replenish the stock, it’s just

that the cycle time is quite long.

This is OK for companies with really deep pockets and really mundane

things – industrial things. I’m not

sure if we could find such a company still doing this today, well at least

not on major items, but there certainly are stable established industrial

firms who manufacture small volume items in their range once or twice a

year. However, hopefully we are all in

the business of making things to sell rather than making things to store. What would happen then if we are supplying consumer

goods or are making perishable items?

Now if we make 4000 things it’s just quite possible that the market

taste may change, or our competitors may bring out something ”new and

improved” – even if it is only the label, or that some of the stock will pass

it’s “use-by” date before it is sold.

Now we risk not only missing sales if sales are greater than our

forecast, we also have a very real risk of dead stock. So what would happen if instead of making 4000

things once a year we made 1000 things once a quarter or heaven-forbid 333

things every month, or 83 and bit every week?

Oops, round that up to 84 for safety – no make it 85. Can you see where we are heading? We are always replenishing whether with

4000 things or 85 things, but with increasingly smaller quantities and

increasingly higher frequency.

Moreover, because we are externally constrained and have processing

capacity to spare, we can chase any localized market spurts, and we can also

drop off quickly with any market downturns.

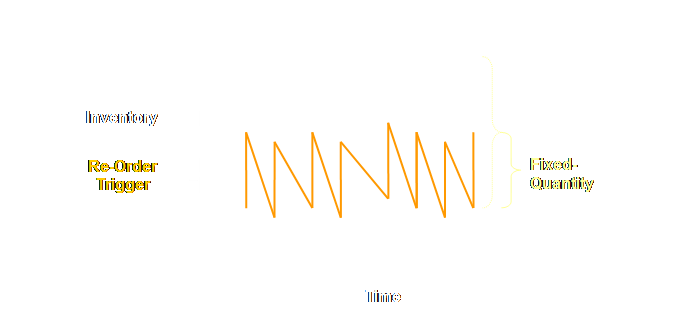

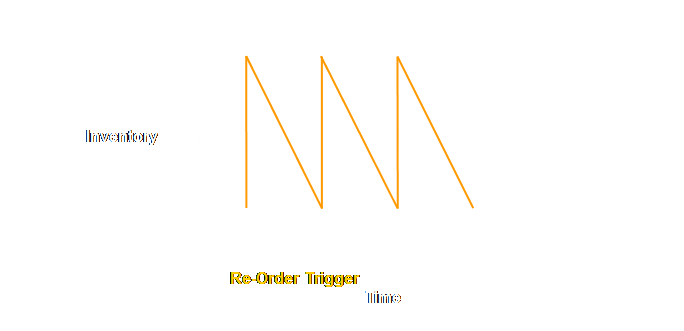

In a word we have become responsive. Let’s examine this graphically. Let’s retrieve our diagram for a

hypothetical stock item from the finished goods section. A perfect saw-tooth diagram.

We know from discussions of batch sizing throughout

this site that reducing the process batch size will reduce the amount of

inventory required to be held in finished goods and that there will be a

equivalent increase in replacement frequency.

Let’s draw this.

Effectively as batch size decreases the maximum

stock in absolute terms approaches closer and closer to the re-order point

stock level. Of course the ideal batch

size would be a unit of 1 – single piece transfer/just-in-time. Therefore replacement in a processing environment is

characterized by; Fixed

Re-Order Quantity & Variable Re-Order Frequency The process requires a finished goods stock – but it

should be as small as possible to decouple the customer from the

process. The customer can still get

stock immediately, and the process replaces it with as small a batch as

possible. In re-order point systems the batching policy is

explicit. However, in some min-max

systems the batching policy may be more implicit; “the batching policy is

hidden under the size of the max minus the min (1).” The batch size is defined by the physical

and especially the policy constraints of the process. Most manufacturers will recognize the above

discussion as what they term replenishment – and this type of fixed-batch

replenishment does find its way into supply chain too. However, it generates two traps that we

should be aware of and try to avoid. The first trap comes from synchronization. Consider the following.

How could such a synchronization arise in the first

place, from simple chance? Or did it

arise from the last synchronous re-supply from the upstream node? This seems far more probable. Often times we create our own problems for

ourselves. This type of problem

creates large waves in upstream nodes when gentle and continuous downstream

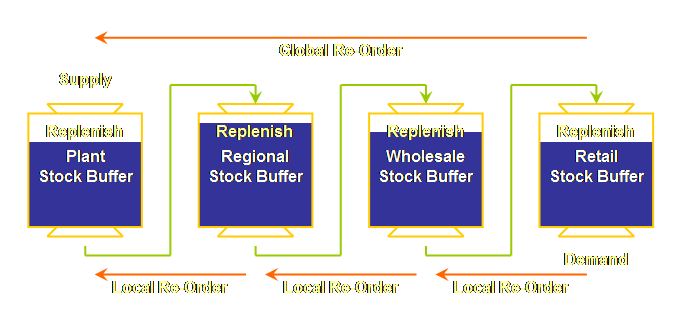

consumption is the reality. The second trap comes from the number of layers or

levels of nodes in the supply chain.

Combine these two situations, a significant number

of layers and some one-to-many relationships and then even a simple linear

supply chain is suddenly not so simple any longer. Let’s look at the alternative then; fixed re-order

frequency with near-instant re-supply; a more common replenishment system

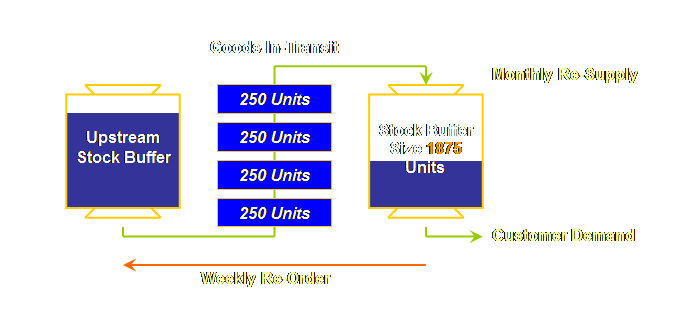

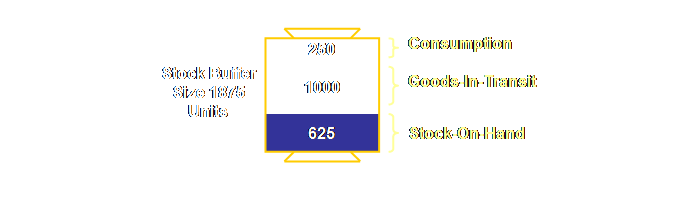

found in supply chains. In supply chain, as opposed to manufacturing, it is

possible to break out of fix-quantity re-orders and instead fix the re-supply

frequency. So we need to investigate

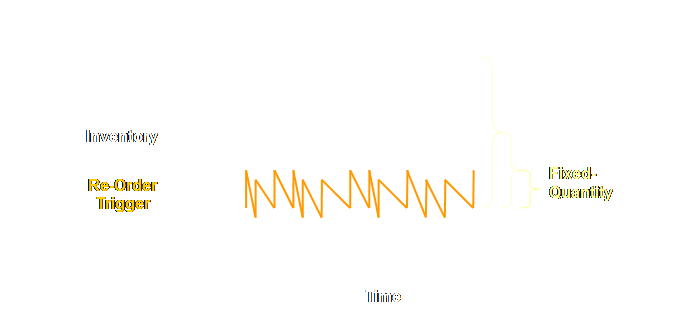

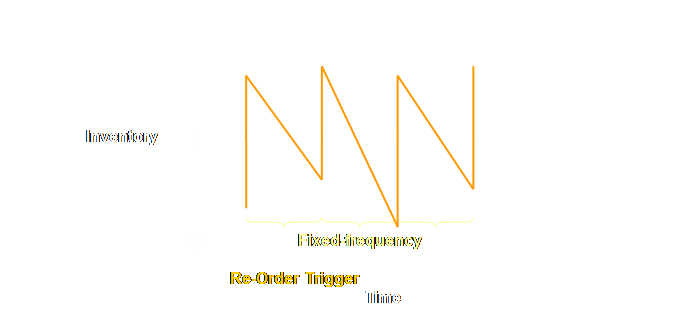

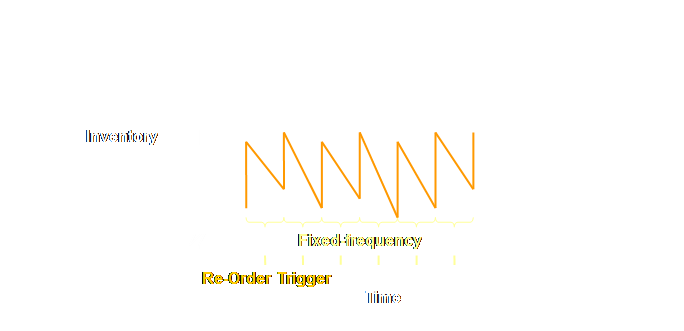

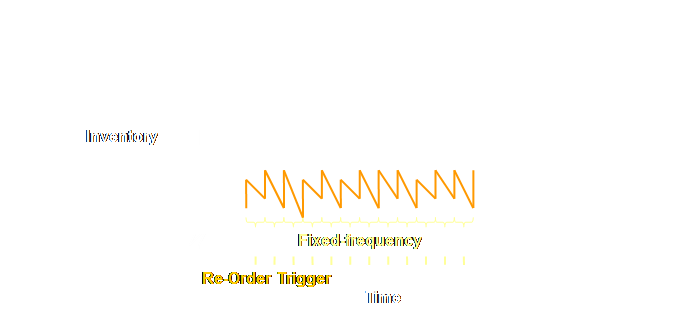

this as well. Let’s start again at the beginning once again with

our perfect saw-tooth graph.

Just as in the processing environment where we could

reduce the quantity in each batch, here we can increase the frequency and

obtain the same effect; reduced inventory of finished goods stock without

degrading service levels. Let’s halve

the re-order date duration and thereby double the re-order frequency. This is the equivalent of ordered once a

fortnight instead of once a month, or ordering once a week instead of once a

fortnight.

Therefore replenishment in supply chain environments

is characterized by; Variable Re-Order Quantity & Fixed Re-Order Frequency Many times the variable quantity that we re-order to

in fixed-frequency re-ordering is in actuality a forecast value for future

expected consumption. Many of the ERP

systems that generate these targets are operated on a monthly cycle ensuring

large quantities that are produced infrequently. The two traps that we mentioned for min/max systems

still operate to some extent. In terms

of the one-to-many relationship and synchronization, if all the nodes

re-order on the same date, this will cause a “”wave” of demand on the

upstream supply nodes when the customer drawdown might have been quite gentle

and uniform during the preceding period.

In terms of the number of layers of levels of nodes, it can still take

a loooonng

time for a signal from the customer node to arrive back at the source node . Depending

upon the order dates it could take as many replenishment cycles as there are

nodes for a point of sale signal to arrive back at the first node. None of this will surprise anyone in supply

chain. But what can we do about it? We know how to significantly reduce the size of a

stock buffer by either smaller quantities or more frequent re-supply. Classically we achieve one by fixing the

other. Hopefully this analysis has

allowed manufacturers to break the fixed batch quantity mind-set that is

sometimes carried over into supply chain.

In supply chain we fix the frequency and this is the path that we will

follow here in our development of replenishment buffers. Let’s have look, then, at this thing called a

replenishment buffer. Let’s examine buffers in a different fashion to the

saw tooth diagrams that we have used to date.

Let’s draw some fixed-frequency replenishment buffers over a complete

cycle and see if that further helps to draw the distinction between the two

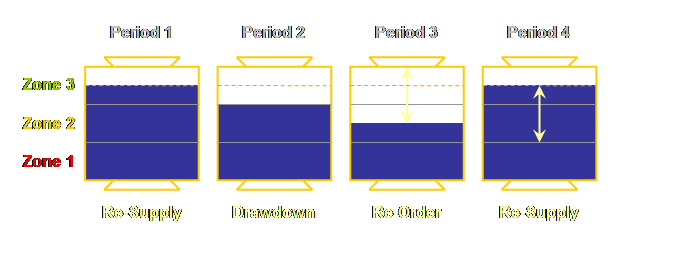

environments of operation – processing and supply chain. Let’s first look at normal

demand.

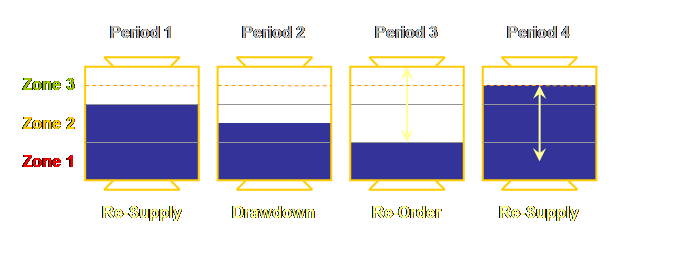

Let’s have a look at this system if we started with

a relatively less stock in the buffer

to being with but at the same rate of drawdown.

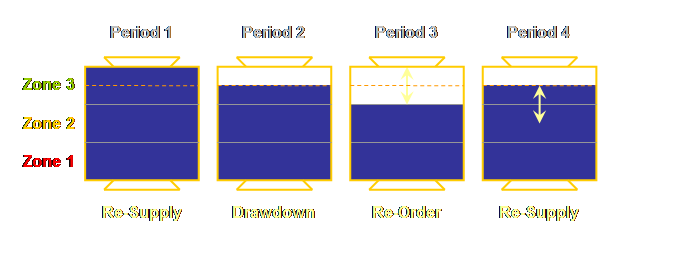

What then if we were to start with a relatively more stock in the buffer to begin with but at

the same rate of drawdown? Let’s look

at that.

In this particular example there appears to be some

robustness about the buffer design with respect to the rate of stock

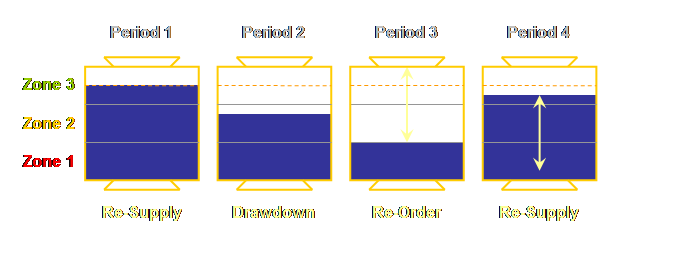

drawdown. Therefore let’s look at both

a substantially greater and substantially reduced rate of drawdown. What happens then during a period of heavy

drawdown? Let’s use our original case

but we will increase the rate of drawdown by 50%. Let’s have a look at that.

Let’s then have a look at periods of light

demand. Again we will use the initial

case but we will decrease the demand by

50%.

On the drum-buffer-rope page I tried to make a

conceptual distinction between fix-frequency buffers of make-to-replenish and

the classical fix-quantity buffers of re-order point and min/max of

make-to-stock. I suggested that

fixed-quantity min/max buffers might be viewed as filling from the bottom and

that fix-frequency replenishment buffers – like we have just drawn above –

might be view as filling from the top.

If we fill from the top, then we need to know just how big the buffer

is. We need to know how to size the

buffer. Let’s pool our knowledge of

decreasing batch size and increasing shipment lot frequency and address how

to size a supply chain replenishment buffer. A supply chain replenishment buffer must protect the

downstream node, or the customer demand if it is the last node, from

fluctuations in both downstream demand and in upstream supply during the

period of interest. The period of

interest is the replenishment time.

The replenishment time we already know is composed of the re-order duration and the re-supply

duration. However, so far we have fairly much assumed

near-instantaneous re-supply. Let’s

continue to do that for a while because I think that it will help us to

understand better the various components of replenishment. Let’s start with a simple case – two nodes.

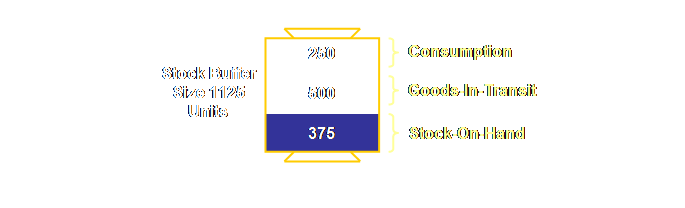

Buffer Size = Average Recent Demand In The

Re-Order Period An initial suggestion for a good value of safety is

plus 50% (3). Such a suggestion

automatically creates a buffer zonation of 2/3rds to 1/3rd (more on that

later). A more recent verbalization for the buffer size is;

the maximum forecasted consumption within the average replenishment time,

factored by the level of unreliability of re-supply (4). It seems that the term “re-supply” was however

used loosely to mean all of the replenishment duration rather than a specific

component of replenishment duration as we are using it here. This was corrected in the Insights program

on distribution and supply chain as; the maximum forecasted consumption

within the average replenishment time, factored by the level of unreliability

of replenishment (5).” Thus the more variable the customer demand, the

bigger the buffer. The more variable

the re-order duration, the bigger the buffer.

The more variable the re-supply duration, the bigger the buffer. The higher the required customer service

level, the bigger the buffer. These

situations are better accommodated in the later verbalizations. With this in mind, however, let’s stick

with the first formula; it will help us to better understand the situation if

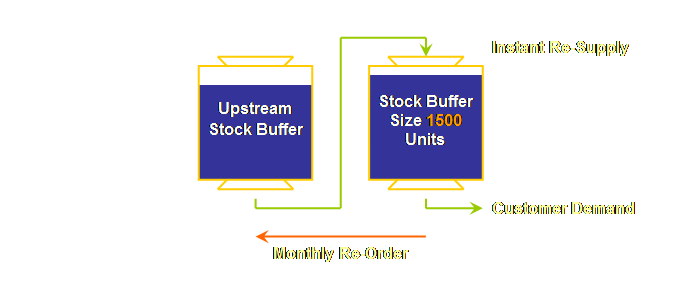

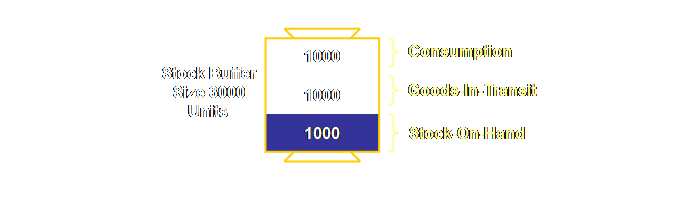

we limit ourselves to this more straightforward case. Let’s assume some numbers. Let’s assume that we sell 1,000 units per

month on average. With near-instant

re-supply our buffer size is 1,500 units.

Lets draw that.

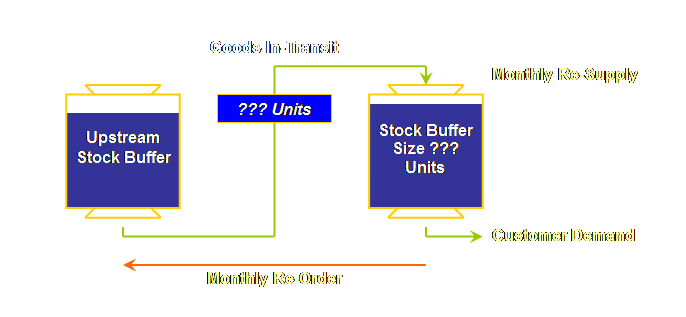

What if we can’t get re-supply next day from across

town? Well, then we have to make the

buffers bigger. Let’s have a look at

that. What if we order monthly but the shipment comes

across country or across the sea? We

have to take that into account too.

Let’s start with monthly re-ordering and a month to re-supply.

But let’s not forget, the objective is not inventory

reduction per se, it is getting the right stuff

to the right place at the right time so that our throughput goes up, so that

our customers come back to us for more (and not our competitors), and so that

our throughput goes up even further. It seems any time someone makes a suggestion for

smaller batches and more frequent delivery, someone else will raise the issue

that operating costs will go up. There

is a very good discussion by Cole on why operating costs should, in fact, go

down while addressing this particular aspect and a myriad of other aspects as

well (2, 3). However, please also

check out the “truck and trailer” analogy in the production page on batch

issues. There are graphs there that are

relevant to supply chain. From these

we can infer that it is very likely that a significant proportion of the

active inventory in any supply chain is in actuality the smaller part of the

total shipment lots. More frequent

re-supply of this portion of the stock will have considerable leverage upon

the whole system without substantially increasing the total shipment lots. Once we have determined the buffer size, how do we

determine the replenishment amount? The only pieces of information that we have are the

buffer quantity that we are aiming for, the quantity present as stock-on-hand

at the re-order date, and any goods-in-transit. Thus the replenishment amount is the

difference, and as depletion will continue to occur until replenishment is

achieved, then the replenishment when it does arrive will be to a less than

the full buffer. Re-Order Quantity = Buffer Quantity –

Stock-On-Hand – Goods-In-Transit + Orders The re-order quantity is fairly much the same as the

proportion that we have been calling consumption above. In fact it should be fairly clear that the re-order quantity replenishes consumption. Of course it would be easier to write “re-order

quantity = consumption” but the amount of consumption only has relevance with

respect to the buffer quantity that we establish. So it has to be determined by difference. But where did that “orders” term suddenly come

from? Well, “that would be the

computer!” You see often times the

order processing people put an order against a stock unit which remains

currently unpicked but nevertheless committed to a customer. The most obvious cause is waiting for

transportation. We could leave the

term out, but seeing that we have made a firm commitment to sell it in the

near future we may as well replace it sooner rather than later.

If your experience is confined to supply chain, it

may seem unusual to even consider why the replenishment buffer should be

determined by anything other than quantity.

However, on the drum-buffer-rope page, we labored the point that in a

manufacturing process the size and activity of the constraint, control point,

assembly, and shipping buffers are measured in units of time. This is a unique feature (#). It is a consequence of the acknowledgement

of the existence of a singular constraint within a process. For constraint buffer activity we said

that; At a manufacturing constraint an hour is

an hour but the number of units may differ. The number of units differs due to the fact that different

types of product using the same constraint may use different amounts of

constraint time. The unique

perspective brought about by the recognition of a singular constraint allows

us to define the length of the buffer in time also. Essentially the buffer is sized and “sees”

the duration from the gating operation to the constraint due date. Moreover the buffer “sees” committed demand

– work that has been released to the system. Why then, doesn’t this carry over into supply chain

replenishment if it is so important in drum-buffer-rope manufacturing? Well, in a way, it does as we shall

see. Replenishment buffer size and

activity is defined by time but is measured by quantity. Why is this? Let’s examine replenishment buffer activity first. The clue comes from the buffer sizing discussion

earlier when we used the “average recent demand.” Even when the re-order and re-supply

periods have military regularity to them, the actual amount will vary because

the demand rate varies over time.

Therefore, the amount of time or demand that our material stock can

“cover” is variable. Sometimes demand

is high and we utilize units faster and over a shorter period. Sometimes demand in low and we utilize

units slower and over a longer period.

But a unit is still a unit.

Thus; At a replenishment node a unit is a unit

but the hours may differ. In replenishment where nothing is undergoing

conversion or combination – there is no processing – then we use units of

quantity to measure buffer activity. What about the replenishment buffer size then? The unique perspective brought about by the

designation of a replenishment node allows us to define the length of the

replenishment buffer in time.

Essentially the buffer is sized and “sees” a duration that extends through

one period of the re-order and re-supply cycle. However, the buffer now “sees” uncommitted

demand – we can not tell how much we will sell in the next hour or day or

whatever. Therefore, we must once

again substitute “non-variable” units of stock in place of the “variable”

amount of time or demand that they “cover.”

Thus the replenishment buffer size is also measured in units of

quantity. Both manufacturing and supply chain buffers are defined

by time; the period that the buffer “sees.”

However, in supply chain we measure buffer size and activity in

units of material, and not in units of time. We called replenishment the motor for supply chain

solutions. Re-order and re-supply

duration determine the buffer size and are the characteristics which

configure the system. Buffer

management is the monitoring and control function that we use once the

configuration is in place. Schragenheim describes the role of buffers and

buffer management in replenishment as follows. ”Instead of trying to be very precise in

very uncertain situations (like using sophisticated forecasting techniques),

TOC strives to build a robust design that is good enough. The initial parameters are based on crude

forecasting that is complemented by crude assessment of the variability of

both market demand and replenishment time.

What complements good-enough planning is a very flexible and

priority-driven execution control system that is capable of taking care of

the exceptions.” “Buffer management is

a control mechanism. The idea behind

it can be summarized as: identifying situations where the planned protection

is almost exhausted (1).” Buffer management is a benign form of control,

basically, it is reporting by exception.

Thus we focus on the few things that are locally important and we

don’t focus on many things that are locally unimportant. There are two mechanisms by which we can manage our

buffers. The first and older method is

buffer zonation, Schragenheim and Dettmer call this “traditional buffer

management (6).” The second and more

recent approach is buffer status (1).

Schragenheim and Dettmer described the precursor to buffer status (in a

manufacturing make-to-stock environment) as the “S-DBR approach” to

controlling uncertainty and variation (7).”

Let’s work through the buffer zonation approach first, leading onto a

discussion on local performance measurements, and then we can examine the

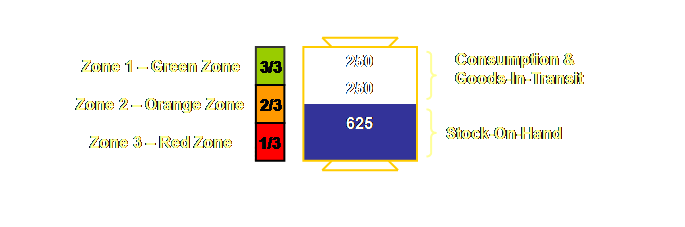

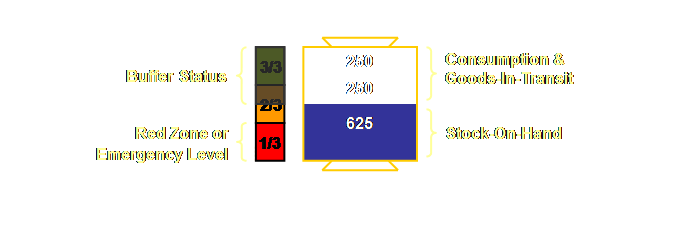

more recent buffer status approach. In fact we have mentioned buffer zones in passing

throughout this page. As with the

manufacturing logistical solution (or project management for that matter),

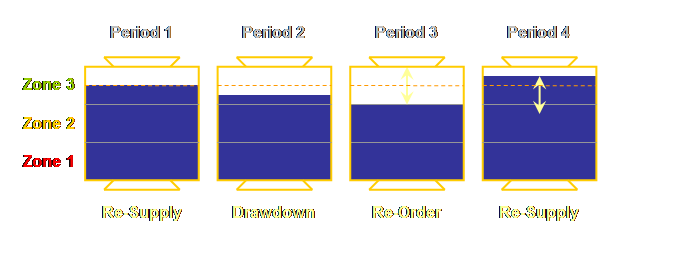

the buffer is divided into three. These are referred to – from nearly full to

nearly empty – as; zone 3 (the green zone), zone 2 (the orange zone) and zone

1 (the red zone). It refers only to

the stock-on-hand, the stock that we have that we can use to immediately

fulfill a new order. Let’s show this.

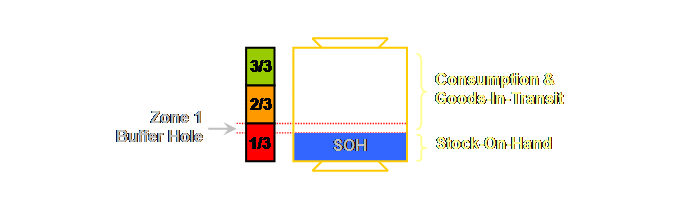

A zone 1 stock buffer penetration offers us two sets

of information. The first is a simple

record of an incidence – we have a hole.

The second piece of information is the magnitude of

the depletion. Now things become more

interesting. Unlike a make-to-order

manufacturing environment, where each job is discrete with an absolute

delivery date, and the magnitude of a buffer hole can be quantified when the

job is finally completed, make-to-stock is continuous – we continuously

replenish and customers continuously deplete our replenishment. So, we can not put a mark in the ground

that says “hole closed on this day.”

Instead we must continuously monitor the number of units missing from

zone 1 and the number of days that they are missing for. We must record the number of units “missing” from

zone 1 each day that any units are missing and we must aggregate this over

our reporting period – be that a day, a week, or a month. The measure is unit-days late. Note that it is an absolute measure based

upon the quantity of material and the amount of time. Now we must put a value to this

measure. Let’s look at local

performance measures. There are two local performance measures. They are measures of local unit-days-late,

which we have just examined, and local unit-days-wait. We can attach values to these in for-profit

systems and call them throughput-dollar-days late and inventory-dollar-days

wait. We know the fundamental or system-wide measures for

a for-profit system; they are throughput (sales minus totally variable costs

excluding direct labor), operating expense (including direct labor), and

inventory (all capital investment).

However we can’t and don’t want to apply these to sub-systems or else

we are going backwards to a reductionist/local optima approach. In a supply chain however, it may be that

each subsystem is indeed a separate business with its own throughput,

inventory, and operating expense.

Nevertheless we can still use the two local performance measures to

ensure alignment of the whole supply chain. If we can’t supply an order ex-stock at the time

requested then that order is considered to be late. We operate the system to take account of

dependencies and variation so we would hope that nothing is late. The measure of lateness is the value of the

goods (throughput) multiplied by the number of days late to obtain throughput-dollar-days. It seems that we can apply this measure to

two different places. We can apply

throughput-dollar-days lateness value to zone 1 buffer penetration for internal

measurements (8) and order non-fulfillment for external measures (4). For the external measure we should aim for

a zero value. Thus, whenever there is

a hand-off within the supply chain we can expect to use a value of

unit-days-late. Let’s draw this situation for a simple supply chain.

Schragenheim uses the term “buffer status” to refer

to buffer consumption or buffer penetration (1); where buffer status is: Buffer Status = (Buffer Quantity –

Stock-On-Hand) / Buffer Quantity In this situation the buffer status value is the

inverse of the proportion of stock-on-hand.

Let’s draw this.

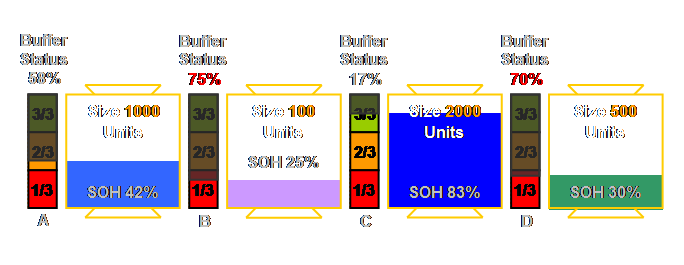

Consider the buffer status of 75% for stock item B

above. In absolute terms this

represents an incursion of (0.75-0.66) by 100 = 9 units. Consider the buffer status of 70% for stock item D

above. In absolute terms this

represents an incursion of (0.70-0.66) by 500 = 20 units. We might be tempted to pay more attention to the

goods-in-transit for stock D than the goods-in-transit for stock B, but stock

B is more important, the buffer status is worse. Cole considers that there are 3 reasons that might

lead to a resizing of a buffer once it has been set (2). They are; (1) Buffer is too small (2) Buffer is too large (3) Seasonality or promotions Using Schragenheim’s criteria, a buffer is too small

if penetration into zone 1 is too frequent and too large if penetration into

zone 1 is too rare (1). Using average values of consumption and re-order and

re-supply as we have here, it might be assumed that half the time our zone 1

would be too small and half the time it would be too large. In fact this is correct, but the period

over which it concerns us is near the end of each re-order period. So, for instance, if we have a monthly

re-order period we may penetrate into the red zone – near the end of the

period. But how long do we do this

for? If it is one or two days out of

20, then we have a zone 1 penetration of 5-10% of the total time – not 50% of

the time as we might first expect. Let’s look then at seasonality. There is a demand for electric fence energizers for

pastoral farming. The electric fences

– often a single wire set a little below a person’s hip height – keep cattle

in the pasture eating what they should eat and out of the areas that they

shouldn’t eat. And although cattle can

stretch their necks a surprisingly long way, on the whole this is a very

effective system. Dogs who insist on

holding their tails upright while passing under these fences will also attest

to their efficacy. However, grass grows at the greatest rate in spring,

and this is often when electric fences are used to “break-feed” new

pasture. Thus the majority of the

demand for electric fence energizers occurs within 2-3 months. How do we ensure that we sell all the

energizers in all the model configurations that are desired in the quantities

required without either leaving some demand unsatisfied (because then the

sale may fall to a competitor) and without leaving excess and unsold stock to

carry for at least the next 9-10 months? We need to set a seasonal buffer for this

example. Firstly why don’t we estimate

the maximum expected sales that we could hope to make by the end of the peak

sales period. Secondly we need to

determine the available production capacity during the peak period. We then subtract the amount that can be

produced during the peak sales period from the maximum sales amount and this

becomes our pre-peak target buffer. We

build to this buffer prior to the season and then once the season is underway

we can chase the peak with our existing capacity. We can therefore be assured that we won’t

get left with too much excess stock to carry and we are also assured of

meeting our most favorable estimate for sales. We examined this topic on the drum-buffer-rope page

in the production section, but let’s revisit it here. Supply chains can occur “free standing” as

we have examined then here, or they can occur in combination with

manufacturing either after or before a manufacturing process. Now that we have a much better

understanding of how to utilize replenishment buffers lets re-check this

understanding against raw material or inwards goods stock buffers. Let’s draw a basic diagram of the

situation.

Vendors, unfortunately, are one of those groups were

it is very easy to externalize the challenges of managing the system and

blame the vendors. Well, we can do that.

However, ask yourself, will it cause anything to improve? We might even be able to change vendors –

until the next vendor goes “bad” on us too.

Vendors really are beyond our span of control and most often our

sphere of influence as well, so about the very best thing we can do is to

buffer ourselves against their impact upon our business. We can modify our basic replenishment formula

to account for vendor behavior. Here

it is. Buffer Size = Maximum Expected Demand In The

Longest Re-Order Period Such a more conservative buffer sizing; “maximum

expected demand” and “longest re-supply period,” may cause some inventory

levels to go up, but we have to ask ourselves whether we are in the business

of making money through sales or in the business of saving money through

reduced inwards goods. If we are still

not happy, then we should try and persuade our vendor to own the goods until

we consume them. That way the vendor

will learn something about the cost of their own (un)reliability. Better still, we should try to reduce the

inventory size (if necessary) by increasing the frequency of the re-order and

decreasing the duration of the re-supply while fully protecting our own

throughput. How can we compare what we have learnt here with

traditional supply chain management?

Maybe it is best to think of current supply chain management as the

reductionist/local optima solution for distribution, just as MRPII is the

reductionist/local optima solution for processing or critical path is for

project management. Traditional supply

chain management uses forecasting to try and overcome the long lead

times. The long lead times generate

large work-in-process but somehow as a consequence we never have all the

right things in the right place at the right time. Instead we have challenged the very need

for such long lead times. No matter

how good or how expensive our software solution is, if it is using

traditional reductionist philosophy; we won’t be able to put the right

protection the right place to drive system profitability. The only way to overcome that is to use

replenishment buffering, we can best evaluate the impact by examining the two

traps that we discussed earlier. The

first was synchronization caused by a one-to-many relationship between source

and demand.

What then, if we have several layers of nodes in our

system?

If we are willing to challenge that we must forecast

and that re-order and re-supply times must be in-frequent then there is much

we can do to ensure that the supply chain functions with precision and

profit. We have looked at 2 replenishment environments; 1. Fixed re-order quantity variable

re-order frequency – batch lot manufacturing 2. Variable re-order quantity fixed re-order frequency – shipment lot supply chain But there is a third 3. Variable re-order quantity and variable re-order frequency We touched upon this in the drum-buffer-rope page in

the section on manufacturing make-to-stock and discussed the rules required

to action it. Within a manufacturing

system it is possible to launch new stock orders at any time based upon a new

stock order release priority determined by the relative stock order status

for each stock buffer. Schragenheim

showed how this becomes a self-regulating system (1). There exists a potential to extend this

mechanism into supply chain; especially those that are computerised. Consider once again that replenishment is composed

of the following; Re-Checking, Re-ordering, Re-Supply, & Re-Stocking It stands therefore that whenever re-checking is

more frequent than re-ordering, and re-ordering is already frequent, that

there may be re-checking periods when there is no re-order quantity required,

or the re-order quantity for a re-order period is smaller than one that we

wish to commit to. In this case our

re-order frequency has become variable rather than fixed. The more frequently that we are able to

re-check and re-order the more likely that our re-order at any one time for

any one stock may be less than we wish to commit to. Thus we have variable re-order quantity as before,

but we now also have variable re-order frequency as well. This appears to me to be a natural

progression as shipment lots become more frequent and smaller. It is an ideal which we should aim to work

towards.

We can summarize this as a simple table.

Using correct buffer sizing criteria we can ensure that

we can always supply the next node in our supply chain to the desired level

of service regardless of the variability or reliability of our vendors or of our

customer’s demand. Moreover, reduction of the re-order duration and

reduction of the re-supply duration can reduce the overall inventory in the

system substantially while increasing overall service levels. Nevertheless, the objective is not

inventory reduction per se it is

increased throughput. Next let’s see how we can apply this to two particular

configurations, divergent supply chains in distribution, and convergent

supply chains in marshalling. (1) Schragenheim,

E., (2002) Make-to-stock under drum-buffer-rope and buffer management

methodology. APICS International

Conference Proceedings, Session

I-09, 5 pp. (2) Cole, H., (1998) Implementing distribution –

layers 4-5. Video JMT-16, Goldratt

Institute. (3) Cole, H., (1998) Distribution – layers 1-3. Video JMT-6, Goldratt Institute. (4) Goldratt, E. M., (2002) Theory of Constraints

self learning program of distribution and supply chain. CD-ROM, Goldratt’s Marketing Group. (5) Goldratt, E. M., and Goldratt, A., (2003)

Insights into distribution and supply chain.

Goldratt Marketing Group. (6) Schragenheim,

E., and Dettmer, H. W., (2000) Manufacturing at warp speed: optimizing supply

chain financial performance. The St.

Lucie Press, pp 123-135. (7)

Schragenheim, E., and Dettmer, H. W., (2000) Manufacturing at warp speed:

optimizing supply chain financial performance. The St. Lucie Press, pp 175-207. (8)

Schragenheim, E., (2003) Measures and trust in SCM. PowerPoint presentation link to CIRAS Center

for Industrial Research and Service - Iowa State University. This Webpage Copyright © 2003-2009 by Dr K. J.

Youngman |